NZ Prosthetic Eye Services – Enhancing eye socket health and comfort in prosthetic eyes.

Company Profile

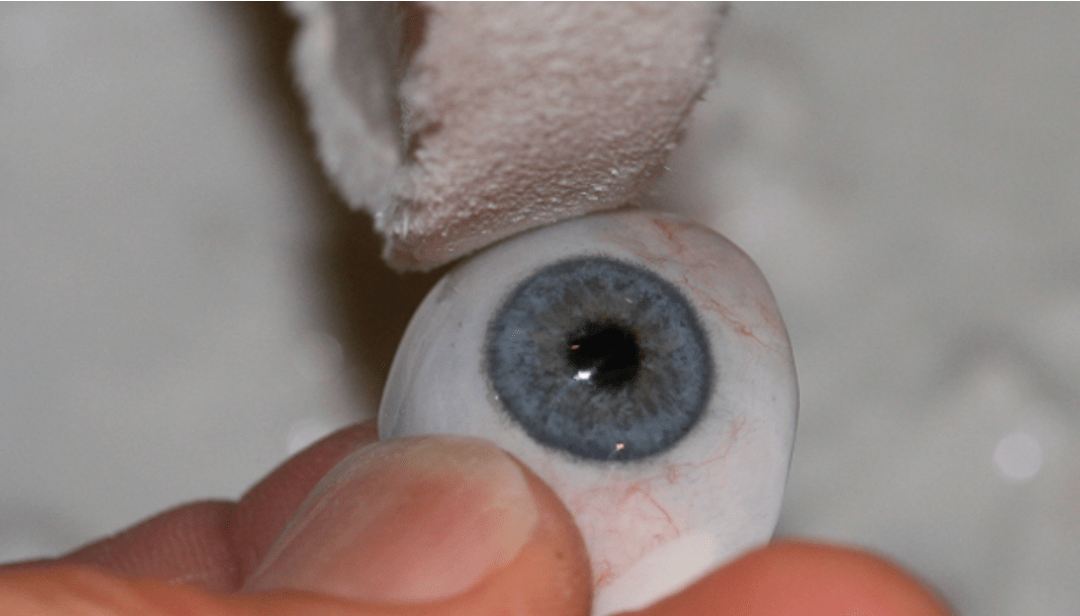

The New Zealand Prosthetic Eye Service (NZPES) is a specialist practice that makes, fits and maintains custom-fit prosthetic eyes out of poly(methyy methacrylate) (PMMA).

The Relationship

PMMA is hydrophobic causing the spread of tears over the prosthesis to be interrupted, making it less comfortable to wear. Solutions such as hydrophilic coatings are not practical to apply in a clinical setting at NZPES and the company needed to create a prosthetic eye that preserved the positive traits of PMMA with the added functionality of lower irritation for the wearer.

NZPES was seeking solutions and contacted NZPA because of longstanding expertise in polymeric materials synthesis and modification. Several technologies were discussed between NZPA and NZPES. When NZPA suggested that modification to the base polymer could produce a more hydrophilic material the client was keen to pursue this solution. The research was carried out under a Callaghan Innovation Getting Started grant and conducted and administered by the NZPA. The project involved modification to the main chain of the polymer to introduce hydrophilic properties required for wearer comfort.

The Impact

NZPA quickly brought in scientific experts to address the challenge of developing a new, non-toxic hydrophilic material for fabrication of the prosthetic eye within 6 months of R&D to commercialize the findings. Eye socket health and comfort in prosthetic eyes has been enhanced for many prosthetic eye wearers in New Zealand and the development has been publicized through journal publication and presentations at international conferences.

The Value

Dr Keith Pine CEO NZ Prosthetic Eye Service said, “NZ Product Accelerator developed a new material for making prosthetic eyes more wettable and more bio-compatible. This material was tested effectively (in vitro) and is currently being used by 30 participants in a clinical study – early results are promising. The new material has the potential to improve the quality of life of prosthetic eye wearers globally and the breakthrough could not have been achieved without the knowledge, enthusiasm and support provided by NZ Product Accelerator”.